In January 2024, Professors Willy Shih and Mike Toffel led 45 HBS MBA students on site visits to witness the energy transition and innovative sustainable production activities throughout Denmark and the Netherlands, in the second year of their Immersive Field Course (IFC). This is one of nine student essays that highlight their reflections.

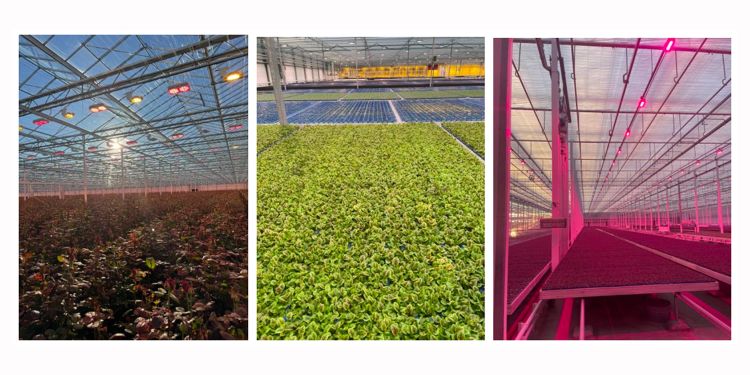

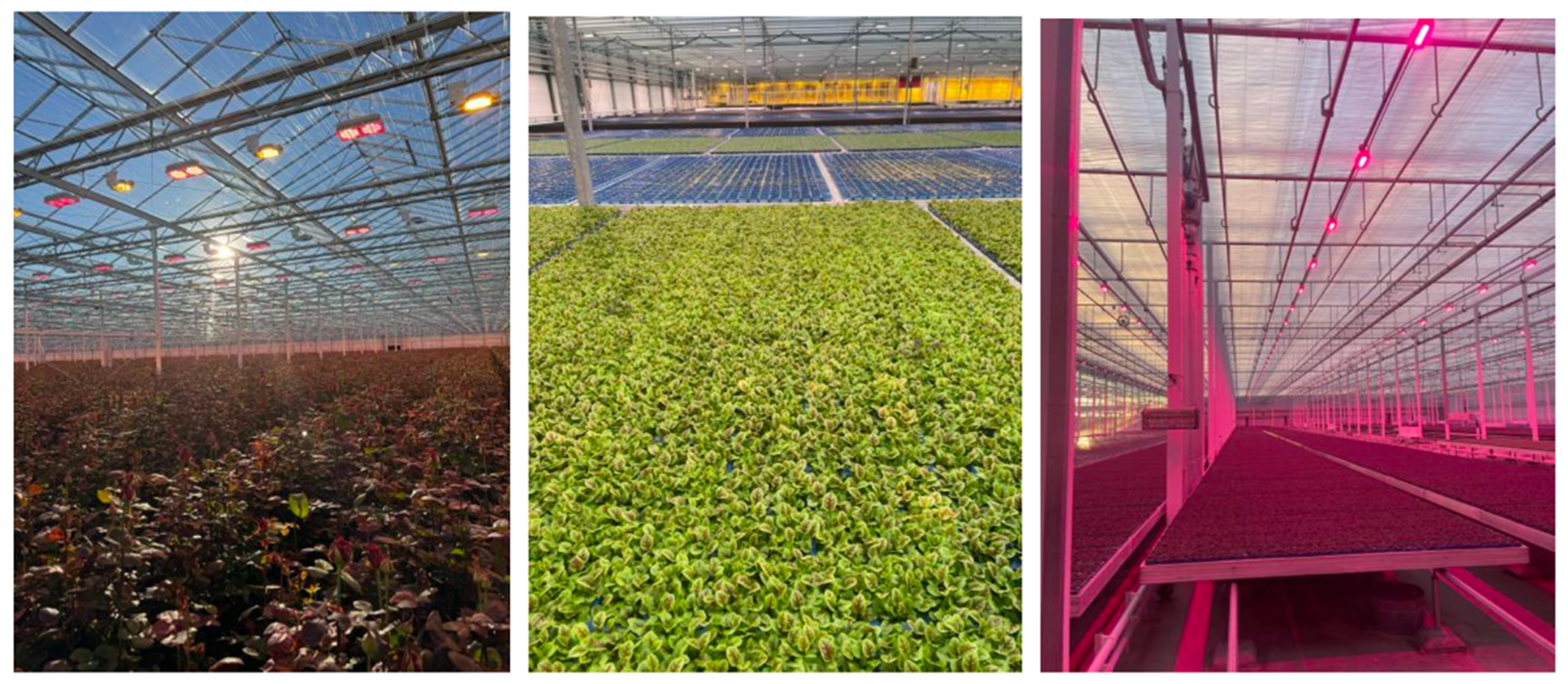

The Netherlands is the second-largest exporter of agricultural products, and it’s not just growing crops - it's cultivating a technological revolution. During our IFC visit, we plunged into the epicenter of innovation: Dutch greenhouses. These aren't your run-of-the-mill structures - they're technological marvels. The trio of Syngenta Tomato Vision, Van den Ende Rozen, and Koppert Cress beckoned us into a world where every leaf and petal is touched by cutting-edge advancements.

- Syngenta Tomato Vision is a research facility focused on creating high-tech, non-GMO tomato varieties for the company’s seed business. Syngenta is a global agribusiness leader focused on crop protection and seeds, and it offers 180+ tomato varieties and has 20+ teams globally focused exclusively on tomato variety selection.

- Van den Ende Rozen is a rose cultivation company known for its high-quality roses and sustainable practices.

- Koppert Cress is a leading producer of microgreens, cresses, and edible flowers. It leverages technologically advanced greenhouses to produce 70-80 offerings. Koppert Cress has invested in several Artificial Intelligence (AI) based technologies for greenhouse production through its incubator, Division Q.

In these Dutch greenhouses, technology rules the roost—from cultivar selection to pest control and automation. We learned that these greenhouses record large streams of data to monitor the internal conditions and make decisions to fine-tune growing conditions for maximum yield.

Cultivar selection. Tomato Vision primarily focuses on R&D around tomato varieties to support a diverse range of growers around the world. Tomato Vision tests thousands of varietal crossings every year and focuses on finding beneficial traits such as improved flavor, longer shelf life, and pest and drought resistance. Traditionally, this has been a highly labor-intensive R&D process, but Tomato Vision has recently begun employing the use of AI to predict optimal varietal hybrids. The company plans to pair this with input from consumer panels, distributor and retailer feedback, and most importantly, feedback from growers. Additionally, the company performs DNA sequencing on most of the varieties it tests to build important datasets that combine traits and gene sequences that can be harnessed for future breeding activities.

Input optimization. Van den Ende employs a highly sophisticated greenhouse, equipped with 70 types of sensors to measure variables such as outdoor wind, water pipe performance, humidity, heat, lighting, and stem height. These sensors serve as critical data inputs for future analysis. The company bases approximately 50% of its production decision-making on human/operator decisions vs. 50% on computer decision-making software.

Pest Management. First tested in Koppert Cress’s greenhouses, PATS, an indoor drone solution, is using AI to automate insect control using computer vision. Pest infestation is one of the most prevalent issues in greenhouse production and is labor-intensive and challenging to combat. This system uses cameras linked to AI models to analyze insect size, speed, and flight patterns, which then feeds information to small drones to intersect an insect’s flight path and kill the pest on impact. This system reduces the need for chemical pesticides. Syngenta’s Tomato Vision greenhouse embraces cutting-edge technology by deploying controlled bee houses to facilitate pollination.

Other applications for technology and sustainability. Syngenta envisions AI providing new possibilities in agricultural gene editing over the next 5-10 years, leveraging AI in conjunction with DNA sequencing technology to enhance virus detection capabilities. This is in response to a tomato virus prevalent across the globe that is devastating to growers’ crops. Syngenta's proactive collaboration with startups underscores a commitment to innovation beyond the confines of Tomato Vision. Meanwhile, Koppert Cress has invested in a geothermal heating facility powered by natural lake cooling to improve energy efficiency as it wrestles with rising energy prices in the EU from the Ukraine War. They also use automated seeding machines to ensure a consistent and uniform plant growth. Van den Ende Rozen embraces automation with an efficient sorting and packing conveyor system, streamlining the rose grading and packaging process. Moreover, the greenhouses we visited were using technology to boost productivity through energy optimization and the color of lighting.